About Us

SAREL Consult GmbH is an independent firm, specialising in development process optimisation, safety & reliability assessment, as well as training. The safety and the reliability of our client’s products is at the heart of our activities; this may include sensitive projects. Therefore, we are committed to working in partnership with our clients, thus building a trusting relationship, which forms the basis for their success. We support your company throughout the entire development process of complex systems, starting from risk assessment of malfunction, classification of failure consequences during the concept phase of development, to defining safety requirements for system design. We provide safety analysis according to international standards:

- Aviation: SAE ARP 4761, SAE ARP 4754 A, RTCA DO178 B/C, RTCA DO254

- Automotive: ISO 26262

- Railmotive: EN 50126, EN 50128, EN 50129

- Agricultural Engineering: ISO 25119

- Medical Engineering: EIC 60601

- Process Industry: EIC 61508, EIC 61511

Board of Directors

The founders and managing partners of SAREL Consult GmbH, Dr. Andreas Vahl and Dr. Uwe Wieczorek

have a wide range of experience on safety and reliability engineering and consulting in the aviation industry.

More

Less

Dr. Andreas Vahl

Dr. Andreas Vahl developed the basis of the software tool SyRelAn (System Reliability Analysis) during his PhD Thesis at the Technical University Hamburg-Harburg and implemented the tool when engineering consulting was founded. As a system safety and reliability expert he gained experience working at Airbus. In addition to holding various management positions in Airbus Research & Technology he was appointed as the managing director of an Airbus partly owned subsidiary.

Dr. Uwe Wieczorek

Dr. Wieczorek also received his Doctor Degree in Engineering at the Technical University Hamburg-Harburg. He gained twelve years of experience as a system safety expert at Airbus and was the A350 Safety & Reliability Coordinator.

Consulting

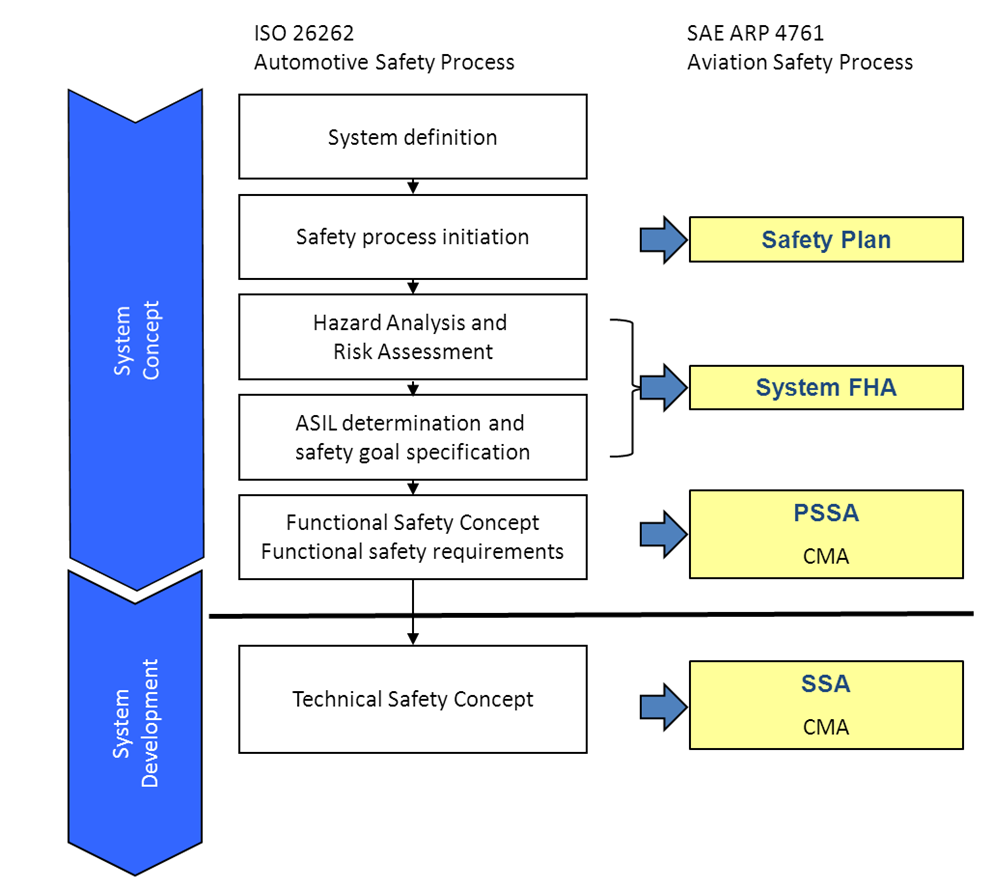

Systems Safety during System-Development Process

Safety and reliability requirements play a major role in systems development and

systems architecture. Neglecting safety requirements can result in costly design

changes in the late phases of the product life cycle. We provide support for the

integration and optimization of functional safety management, as well as the compliance

demonstration of your system development process.

More

Less

Ensuring product safety is in every company’s interests so as to prevent any damage to the reputation and competitiveness of the company. In industries where legal regulations are enforced, product safety has an even higher priority and compliance to the rules must be guaranteed. The resulting safety requirements have significant impact on the development of safety critical systems. For efficient application of the rules, the safety process must be integrated into the development process. Early implementation of safety expertise is essential to ensure that certification is demonstrated and to avoid costly design changes in the late phase of the product development. Therefore, we focus on supporting you during the integration and the optimization of functional safety management and compliance demonstration in your system development process. Our consulting services consider the entire life cycle of your products.

Our Services

| a. | Analysis of development processes und optimization. |

| b. | Integration of safety expertise in your system development according to the following standards: |

| 1. | Aviation: SAE ARP 4761, SAE ARP 4754 A, RTCA DO178 B/C, RTCA DO254 |

| 2. | Automotive: ISO 26262 |

| 3. | Railmotive: EN 50126, EN 50128, EN 50129 |

| 4. | Agricultural Engineering: ISO 25119 |

| 5. | Medical Engineering: EIC 60601 |

| 6. | Process Industry: EIC 61508, EIC 61511 |

| c. | Project management |

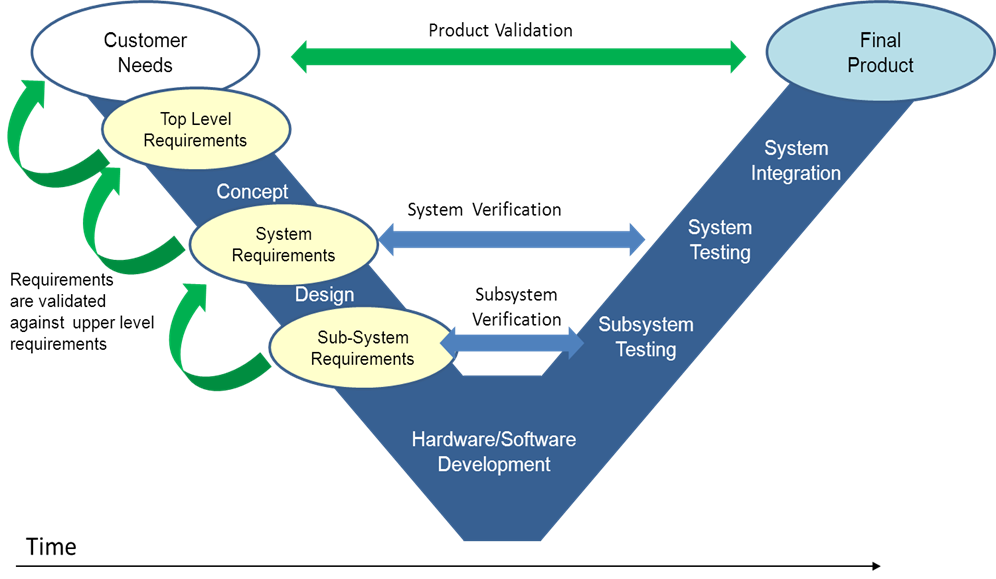

Requirement Engineering / Systems Engineering

The definition, validation and verification of requirements is the foundation for

improving business competitiveness through target-oriented product development. We

help you establish the requirements based on customer needs on system and component

level, internally as well as with your suppliers.

More

Less

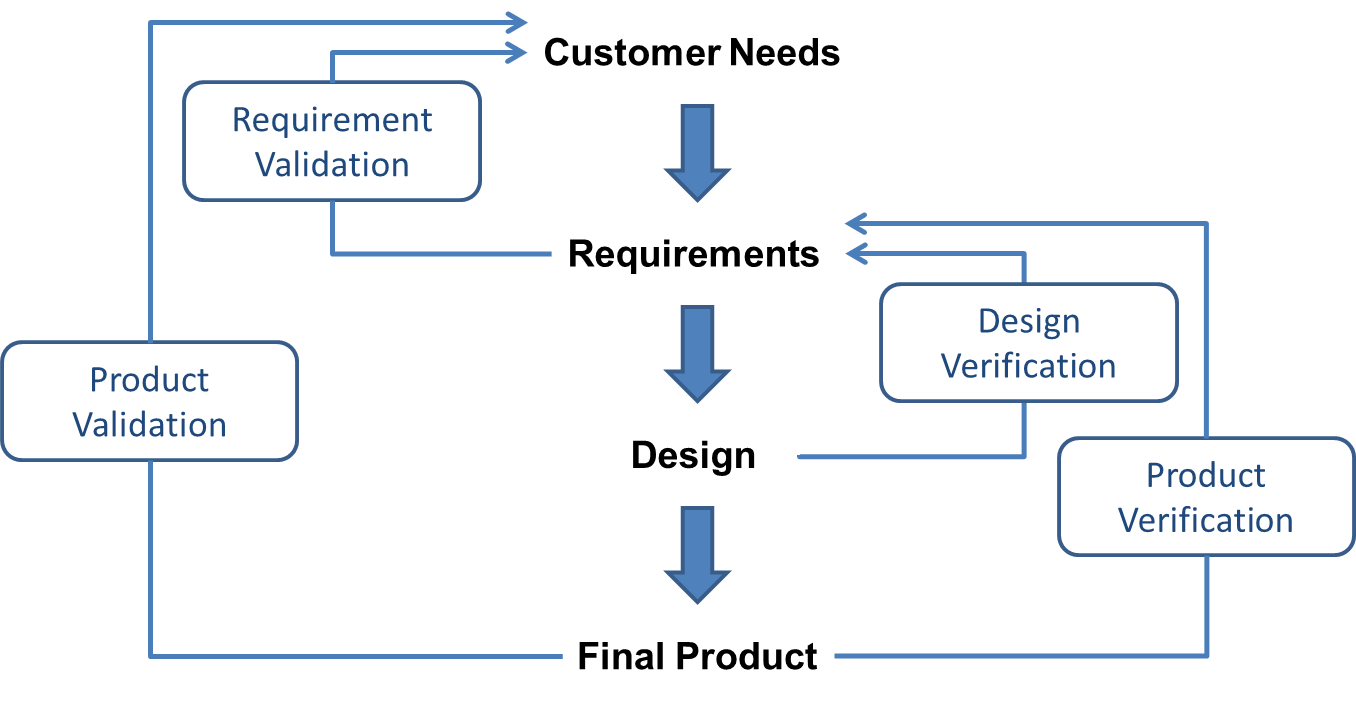

The application systems engineering supplies the necessary methods for target-oriented, efficient product development. The process starts with the definition of customer needs and the desired functionality. The success of a development project depends on the accurate and complete requirement definition in the early development phase. Incomplete requirements or late requirement changes result in re-design costs in the late development phase. This Requirement Engineering process, used in the aeronautic industry for many years, is shown in the following diagram:

Our Services

| a. | Implementation of Requirement Management Process and Requirement Engineering Tools. |

| b. | Determination of requirements based on customer needs for specification on system- and component level. |

| c. | Communication and negotiation of requirements with the suppliers. |

| d. | Support for validation and verification of requirements. |

Aeronautical Certification Support

Assessment of design concepts regarding the certification aspects, and in particular

for new technologies. We can assist you in clarifying the compliance demonstration

with applicable certification rules. As part of this process we can provide support

for the development of design solutions and especially in-service events.

More

Less

SAREL Consult GmbH provides support for the certification of minor/major changes based on CS-25 Large Aeroplane and CS-23 General Aviation. With regard to certification, we focus on cabin systems, including emergency equipment and hydro-mechanical systems.

Our services

| a. | Assessment of certification aspects relating to new technologies. |

| b. | Definition of certification basis and preparation of a certification plan. |

| c. | Negotiation with authorities. |

| d. | Certification Management. |

In-Service Incident Management

In order to ensure efficient and timely response following an in-service incident

the correct processes and procedures need to be in place. Therefore as part of our

services we can assist in the in the development of these processes and procedures

and in addition provide both risk assessment and presentation of the analysis to

the authorities in the event of in-service incidents..

More

Less

The manufacturer / operator is liable for the safety of their products throughout the entire operating life. Despite implementing high quality standards, in-service incidents cannot be excluded. We offer you support and specific solutions in case of in-service incident to ensure your products can be efficiently operated; we also present the incident analysis results to the authorities.

Our services

| a. | Risk assessment of in-service incidents. |

| b. | Assessment of impact on airworthiness. |

| c. | Definition of corrective actions to ensure safe operation. |

| d. | Determination of compliance time of corrective action according to EASA GM21.A.3B(d)(4). |

| e. | Negotiation with authorities. |

Engineering

Safety Assessments & Certification

SAREL Consult GmbH offers system safety analyses throughout the entire development process for various industries. Our services cover the complete safety process according to SAE ARP4761 CS 25.1306 AMC.

Functional Hazard Assessment (FHA)

The Functional Hazard Assessment (FHA) is the starting point of the safety process. The aim of the FHA is to assess the repercussions of malfunctions and functional failures on the safety of the aircraft and its occupants; this contains the definition of safety requirements and failure conditions according to FAR/CS 25.1309. The depth of analysis of the following system safety assessments according to 25.1306 AMC is based on the results of the FHA.

Preliminary System Safety Assessment (PSSA)

Within the scope of the PSSA alternative design concepts are assessed and different system architectures are compared from a safety perspective. The system architecture and the degree of redundancy are determined by the safety requirements. The PSSA defines the system architecture so that compliance with the failure condition can be efficiently demonstrated.

System Safety Assessment (SSA)

The System Safety assessment (SSA) is the continuation of the PSSA. Qualitative and quantitative safety assessments are performed for all significant failure conditions, which were identified in the FHA, to demonstrate compliance according to FAR/CS 25.1309. The quantitative safety assessment is based on fault trees analysis or reliability block diagrams and it is an essential certification document.

Common Cause Analysis (CCA)

The results of the safety assessment are based on the assumption that failures of redundant components are independent events. This assumption has to be verified within the scope of the Common Cause Analysis (CCA). According to AMC 25.1309 it has to be demonstrated that a single event will not result in the loss of multiple redundant components causing catastrophic effects. The Common Mode Analysis (CMA) shall mitigate risk of common cause failure due to environmental factors, development errors and specification errors to ensure that redundant components are independent. Within the scope of Particular Risk Analysis common cause hazards due to external events are considered, e.g.: uncontained engine rotor failure, wheel & tire failure, lightning, bird strike, and appropriate protection means are defined. Common cause hazards that result from the interference of system components located closed to each other are considered within the scope of the Zonal Safety Analysis.

Failure Mode Effect Analysis (FMEA)

The Failure Mode and Effect Analysis (FMEA) identifies potential failure causes on piece part level and their consequences on component and system level. The summary of the FMEA, the Failure Mode and Effect Summary (FMES) provides essential input data for further safety and reliability analyses.

Intrinsic Hazard Analysis (IHA)

The Intrinsic Hazard Analysis (IHA) considers hazards coming from inside the equipment associated with the technology used for the item of equipment. The consequences in the event of failure are assessed and appropriate mitigations means are defined. The IHA is based on application of a generic check list of intrinsic hazard types.

Aeronautical Certification Support

Special Methods

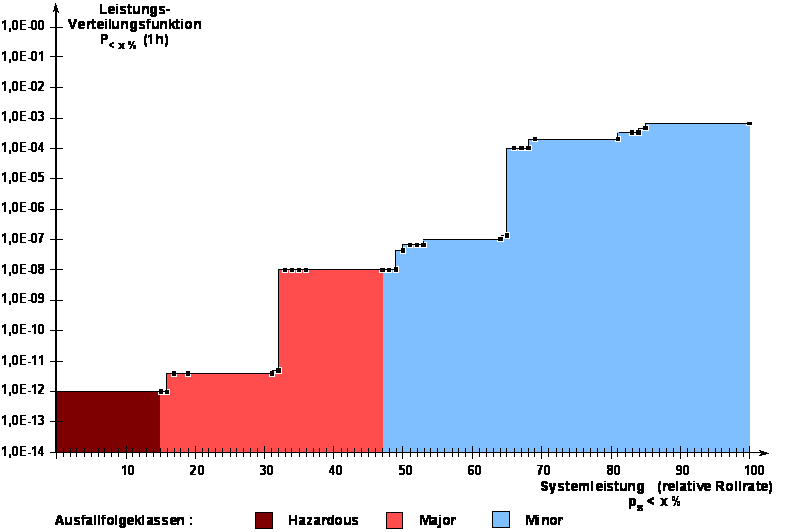

Assessment of Degraded System Configurations

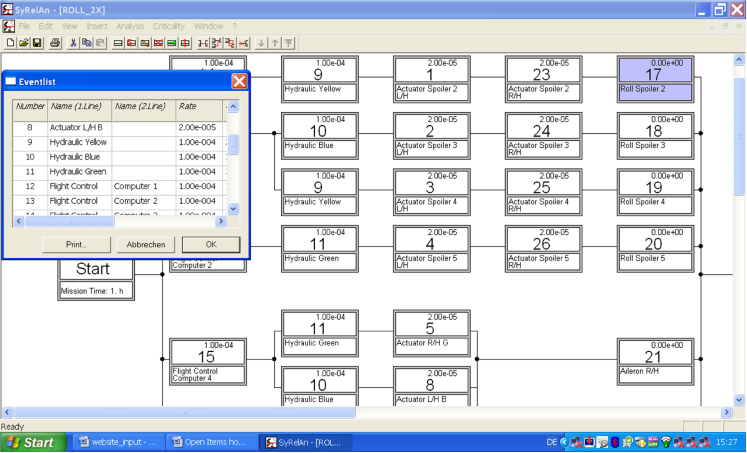

Loss of single components in redundant system architectures generally does not lead to total loss of function, but results in a degraded system performance. On component level the contribution to total system performance can be quantified. SAREL Consult GmbH has developed methods that allows for calculating the occurrence probability of degraded system configurations. The analysis is performed with the Software ToolSyRelAn based on the Reliability Block Diagram for “total loss of function” with the definition of the performance contribution of certain components. SyRelAn compiles the performance distribution function of large systems within seconds.

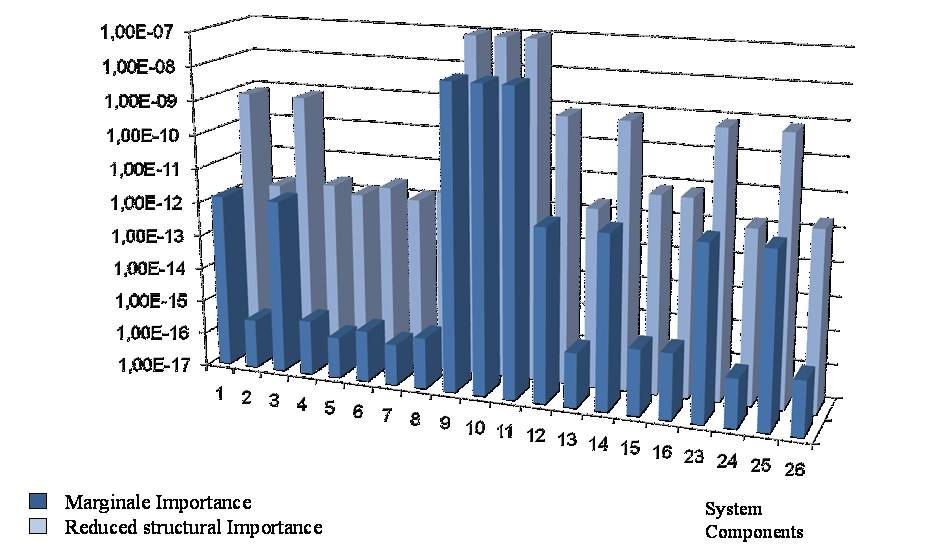

Importance Analyses

An analysis of potential weak spots through importance analyses identifies how components contribute to system reliability and system safety. This allows efficient optimization of complete systems. The software tool SyRelAn contains five importance measures; marginal importance, reduced structural importance, competitive importance, diagnostic importance and minimal cut set importance. Reduced-structural importance is a proprietary development, which allows assessing contribution of components to the system reliability based on the architecture. This method enables analyzing weak spots in the system during the concept phase when component failure rates are not available.Structural Reliability Methods

The resistance of the material and the applied load are considered as stochastic variables described by probability distributions to allow calculation of the failure probability. The rupture of mechanical components and the integrity are now quantifiable, based on operating parameters and the associated safety margins.

Functional Safety - Safety Case

Hazard Analysis and Risk Assessment

Identification of possible risks in case of malfunction of the systems according to applicable standards (ISO26262, EIC61508) and definition of Safety Integrity Level (SIL) or Automotive Safety Integrity Level (ASIL), respectively.

Design Concept Analysis

An assessment of new design solutions from a safety and reliability point of view is essential, particularly in the early design phase. The market success and customer acceptance of technical innovations requires a detailed safety and reliability assessment. We carry out design concept analyses under safety, reliability and economic aspects. SAREL Consult GmbH offers innovative methods and customized software solutions, based on the software tool SyRelAn ( System Reliability Analysis). Particular emphasis is placed on economical optimization through comparison of different system architectures. We support you in the selection and the assessment of new technologies, considering the complete life cycle and various operating scenarios.

Functional Safety Concept

Using the results of the hazard analysis, the functional safety concept is elaborated further. Technical means and operational measures are defined to ensure safe operation; on this basis the system concept is established. The Safety Integrity Level (SIL) or Automotive Safety Integrity Level (ASIL), respectively, will be allocated on subsystem- and component level.

Technical Safety Concept

The functional requirements provide the basis for the evaluation of technical safety requirements for the hardware and the software. Qualitative and quantitative assessment based on Reliability Block Diagram or Fault Tree Analysis will be performed. Technical, probabilistic and interface requirements are defined as well as the test program.

Functional Safety Assessment - Safety Case

SAREL Consult GmbH compiles proof of functional safety according to the generic standard EIC 61508 or related standards for specific industries (e.g. ISO2626, ISO 25119, EN 50126 etc.). The Safety Case demonstrates that the system complies with the requirements regarding functional safety. The results of related analyses, e.g. hazard analysis, functional safety concept, technical safety concept, FMEA, FTA are summarized in the Safety Case.

Failure Mode Effect Analysis (FMEA)

The Failure Mode and Effect Analysis (FMEA) identifies potential failure causes on piece part level and their consequences on component and system level. The summary of the FMEA, the Failure Mode and Effect Summary (FMES) provides essential input data for further safety and reliability analyses.

Operational Reliability & Availability

System down time can result in severe economic damage. In asset intensive industries in particular,

the reliability of capital assets is essential to the company’s financial success. Company’s

reputation and competitiveness suffer if reliability and availability of theirs products to not

meet customer expectations. SAREL Consult GmbH offers wide range of services to analyse and improve

the reliability and availability of your products.

More

Less

In-Service Reliability Analysis

Using field data of your products SAREL Consult GmbH estimate the reliability, failure rate, MTBF and if relevant also the Weibull parameter of the components. We develop specific strategies to improve the reliability taking various factors like stress, environment, system design, manufacturing process and quality management into account.

Reliability Prediction

Within the scope of the reliability prediction component failure rates are determined to provide the basis for further quantitative assessments on system level. The following standards mainly distributed by the Reliability Information Analysis Center (RIAC) provide the basis for the reliability prediction:

- MIL 217 Plus

- NPRD-2011

- FMD-2013

- MechRel Handbook of Reliability Prediction Procedures for Mechanical Equipment - NAVSEA

- SN 29500 (Siemens Norm)

Availability Assessment

We perform an assessment of the availability of your system taking system architecture, failure probabilities and inspection patterns into account. The Markov model is used for the quantitative assessment of repairable systems. We develop concepts to improve life cycle cost (LCC) and economic benefit for your customers.

Systems Engineering

SyRelAn

The Software Tool SyRelAn (System Reliability Analysis) has been developed by Dr. Andreas Vahl to analyse and optimize the safety and reliability of complex systems. SyRelAn uses Reliability Block Diagrams, which are mathematically equivalent to fault trees, but more intuitive for system engineers to work with as they are based on representing the system functionality. Redundancies are represented by parallel paths.

Reliability Block Diagram Analyses

SyRelAn allows describing the system through Reliability Block Diagrams with an interactive graphical user interface. The failure characteristics of the components are defined by failure rates and the dormancy periods. In addition the status failed or active can be assigned to the component. SyRelAn calculates the system failure probability and the system failure rate, depending on the exposure time. The average probabilities can also be calculated.

With SyRelAn hierarchically structured reliability block diagrams can be created. A range in the reliability block diagram can be selected and defined as subsystem. Subsystems can be integrated as basic events, the associated diagram of the subsystem is ordered on a lower layer and can be decomposed on the top layer and vice versa. This feature allows structuring the system descriptions similar to fault trees.

Different formats are available for import and export of data between other software tools.

Assessment of Degraded System Configuration

Loss of single components in redundant systems does generally not lead to total loss of function, but results in a degraded system performance. SyRelAn allows the calculation of occurrence probability for degraded system configurations based on the reliability block diagram for the failure condition “total loss of system”. With this method the effort to perform the safety analysis can be reduced significantly and it allows interactive assessment of different system variants.

Importance Analyses

With the module Importance Analysis of the software tool SyRelAn the following importance measures can be calculated, to assess the contribution of single components on the system failure:

- Marginal Importance

Identification of sensitive system parts - Reduced structural Importance

Analysis of system architectures without component failure rates - Competitive Importance

Detects trigger of system failure - Diagnostic Importance

Identifies contribution to system failure - Minimal Cut Set Importance

System failure scenarios to improve maintenance

The importance analyses are performed based on reliability block diagrams and they offer the possibility to identify in the concept phase the system components that are determining the system reliability and for which optimization has biggest influence on system reliability.

Training

In cooperation with Lufthansa Technical Training GmbH, SAREL Consult GmbH offers training courses explaining the safety process in the aviation industry. The contents of the training courses are based on EASA CS 25.1309 and SAE ARP4761, enhanced with examples and practical exercises.

Trainings Modules

- Functional Hazard Assessment (FHA)

- Preliminary System Safety Assessment (PSSA)

- System Safety Assessment (SSA)

- Failure Mode Effect Analysis (FMEA)

- Failure Mode and Effect Summary (FMES)

- Fehlerbaum / Reliability Block Diagram

- Operational Reliability of Aircraft/Cabin Systems

-

Common Cause Analysis (CCA)

- Common Mode Analysis (CMA)

- Particular Risk Analysis (PRA))

- Zonal Safety Analysis (ZSA)

We are pleased to adapt the training modules on customer needs of different industrial sectors. Within our Reliability, Maintainability und Safety competence center we offer further RAMS Trainings. Please contact us under info@sarel-consult.de

Career

We are looking for engineers and natural scientists with technical background to strengthen our team.

The Scope

- Assessment and optimization of system architecture based on safety and reliability analyses during all project phases.

- Definition of quantitative safety and reliability requirements including safety checks and maintenance intervals.

- Analysis of in-service events and development of solutions.

- Presentation of the results to external customers.

Your Qualifications

- Master degree in engineering science or other technical subject.

- Good knowledge of safety and reliability methods.

- Analytical skills.

- Detailed knowledge of systems engineering.

- Self motivated and independent working.

- Good communication skills in English.

Our offer

- We offer you a responsible and versatile position with scope of development.

- You are working in a highly committed team, where a cooperative working atmosphere and an open communication are the basis for corporate success.

- The company will support your development.

- Competitive salary plus bonus package.

Contact

We are delighted to receive your inquiry.

Dr. Andreas Vahl

andreas.vahl@sarel-consult.de

Mobile: +49(0)151 18240050

uwe.wieczorek@sarel-consult.de

Mobile: +49(0)151 67511009

Address

SAREL Consult GmbH

Dorfstraße 36d

D-25462 Rellingen

.png)